Our Cosmetics Testing Services establish cosmetic products’ safety, quality, and regulatory compliance. As a vast laboratory, we offer complete testing services along with skin and hair care products and equipment designed to comply with internationally acclaimed standards by implementing GMP cosmetics, US FDA, EC1223/2009 (EU cosmetics directives) in the US, EU, and India.

1. Consumer Safety: Chemicals like lead, mercury, and formaldehyde are not produced there.

2. Regulatory Compliance: It governs according to FDA, BIS IS 4707, and EU regulations.

3. Skin Compatibility: Companies must test if professionals test the products they give to skin types and if they are fit for use.

4. Product Performance: CNN’s product is not harmful, and contrary to the manufacturer’s claims, the CNN report states that it is hypoallergenic. No information is available about the toxic substances in the product, such as chemicals or metals.

1. Manufacturers of Cosmetic Products The manufacturers of these product products must also ensure that their products comply with all the relevant rules and regulations.

2. Importers and Exporters: The legislation requires these groups of companies to provide all the documentation needed for imports and exports within the same country.

3. Dealers: The dealers can ensure the quality of the products before selling them.

4. E-commerce Platforms: The testing products can achieve An impeccable delivery system.

we must connect the following points to the main product category, target market, and applicable standards: ISO 22716 and BIS IS 4707.

If the secondary packaging allows the products to be verified, technical documents and materials of the products identified before using them in the laboratory to perform the sample analysis might be required.

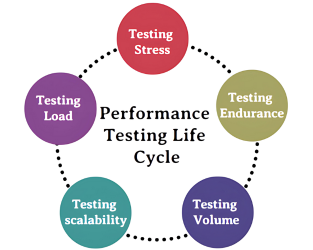

Testing periods include immediate, short-term, and long-term types. The significant tests we run at this time may cause us to accumulate comparative and supplementary information about the products and their safety level.

Issuing a comprehensive result and compliance declaration in addition to the individual account is done.